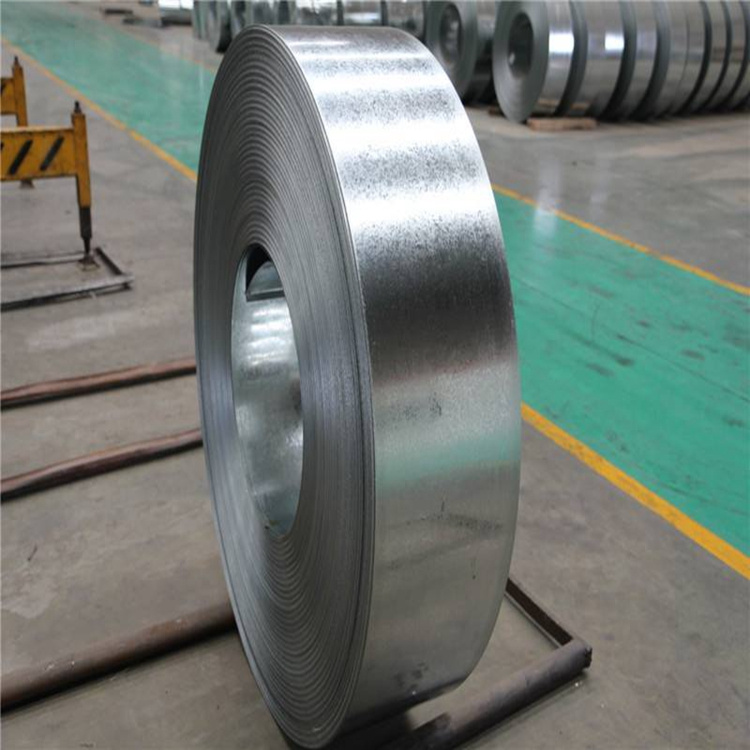

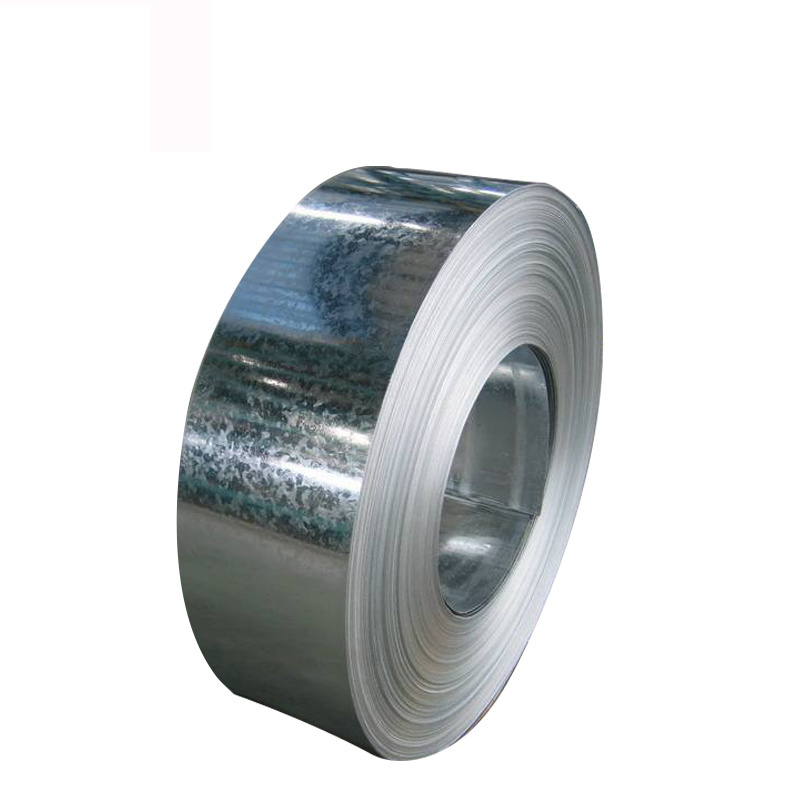

Horganyzott acélszalag

Hagyományos acélszalag-pácolással, horganyzással, csomagolással és egyéb eljárásokkal feldolgozott fémtermékek

Horganyzott acélszalagokHagyományos acélszalag-pácolással, horganyzással, csomagolással és egyéb eljárásokkal dolgozzák fel. Jó korróziógátló tulajdonságai miatt széles körben használják. Főként hidegen megmunkált és már nem horganyzott fémtermékek előállítására használják. Például: fémtermékek, mint például könnyűacél gerincek, őszibarack alakú oszlopok korlátokhoz, mosogatókhoz, gördülőajtókhoz, hidakhoz stb.

A fő cél

Általános polgári

A háztartási készülékek, például mosogatók stb. feldolgozása megerősítheti az ajtópaneleket stb., vagy megerősítheti a konyhai eszközöket stb.

achitechive

Könnyű acél gerinc, tető, mennyezet, fal, vízszigetelő deszka, esővédő, redőnyajtó, raktár belső és külső panelek, szigetelő csőhéj stb.

háztartási gépek

Megerősítés és védelem háztartási gépekben, például hűtőszekrényekben, mosógépekben, zuhanyzókban és porszívókban

Autóipar

Autók, teherautók, pótkocsik, csomagtartó kocsik, hűtős teherautó alkatrészek, garázsajtók, ablaktörlők, sárvédők, üzemanyagtartályok, víztartályok stb.

ipar

Bélyegzőanyagok alapanyagaként kerékpárokban, digitális termékekben, páncélozott kábelekben stb. fogják használni.

egyéb szempontok

Berendezésházak, elektromos szekrények, műszerfalak, irodabútorok stb.

A fehérítő tábla felületének okai és kezelési módszerei

Ha egy kondenzvízréteg tapad a horganyzott réteg felületére, az korrozív vizes oldattá válik, és oxigénnel, szén-dioxiddal, szénhidrogénnel, kén-dioxiddal, korommal, porral és más kémiai gázokkal reagálva a horganyzott réteg felületére tapad, elektrolitot képezve. Ez az elektrolit és a rossz kémiai stabilitású cinkréteg elektrokémiai korróziónak van kitéve, ami porszerű korróziós terméket - fehér rozsdát - eredményez.

A cinkréteg korróziójának fő oka beltéri környezetben a

① Magas a beltéri levegő páratartalma;

② A készterméket nem szárítják és nem tárolják;

③ A cinkréteg felületén egy vízfilmréteg kondenzálódik. Amikor a levegő nedvességtartalma eléri a 60%-ot vagy a 85-95% tartományt, és a pH<6, a korróziós reakció súlyosbodik. Amikor a víz hőmérséklete eléri a 70°C-ot, a cinkréteg korróziós sebessége a leggyorsabb.

A fehér rozsda megelőzésének módja a következő:

① Cinklemezek egymásra rakásakor a felületen nem képződhet páralecsapódás;

2. A raktárban biztosítani kell a légáramlást, és a levegő relatív páratartalma nem lehet 60% vagy 85-95% között;

3. Cinklemezek egymásra rakásakor nem szabad káros gázokat és túlzott porképződést produkálni;

④ Olajozza be és passziválja a horganyzott réteg felületét.

Ha többet szeretne megtudni a horganyzott acélszalagról vagy más acél tartósítási tippekről, kérjük, vegye fel velünk a kapcsolatot.

Tel./WhatsApp/WeChat: +86 136 5209 1506

Email: sales01@royalsteelgroup.com

Közzététel ideje: 2023. július 12.